Kilopascal to Megapascal – How to convert kPa to MPa

Need to convert kilopascal to megapascal? These two pressure units are closely related and part of the SI (metric) system, but they’re used for different scales. Kilopascals are common in weather data, tire pressure, and hydraulics, while megapascals are preferred for engineering, materials testing, and industrial systems that operate at much higher pressures. Converting between them is simple — and essential when dealing with technical specs or global standards.

What is a kilopascal (kPa)?

A kilopascal equals 1,000 pascals, or roughly the amount of pressure exerted by a 10-centimeter column of water. It’s widely used to measure relatively moderate pressures:

-

Weather reports often express atmospheric pressure in kilopascals (standard sea-level pressure is 101.325 kPa).

-

Vehicle manuals list tire pressures in kPa, alongside psi, especially outside the United States.

-

HVAC systems and low-pressure hydraulics rely on kilopascal readings for design and safety checks.

Because it’s easy to relate to real-world pressures, kPa is one of the most common SI pressure units.

What is a megapascal (MPa)?

A megapascal equals 1,000,000 pascals, or 1,000 kilopascals. It’s a much larger unit, used for high-pressure applications:

-

Industrial hydraulics and pipeline systems frequently operate in the MPa range.

-

Materials testing, such as measuring the tensile strength of steel or concrete, uses MPa to express results.

-

Even scuba diving equipment and high-pressure pumps rely on MPa values to rate safety tolerances.

Because it’s suited to intense pressures, MPa is a standard in engineering and technical specifications worldwide.

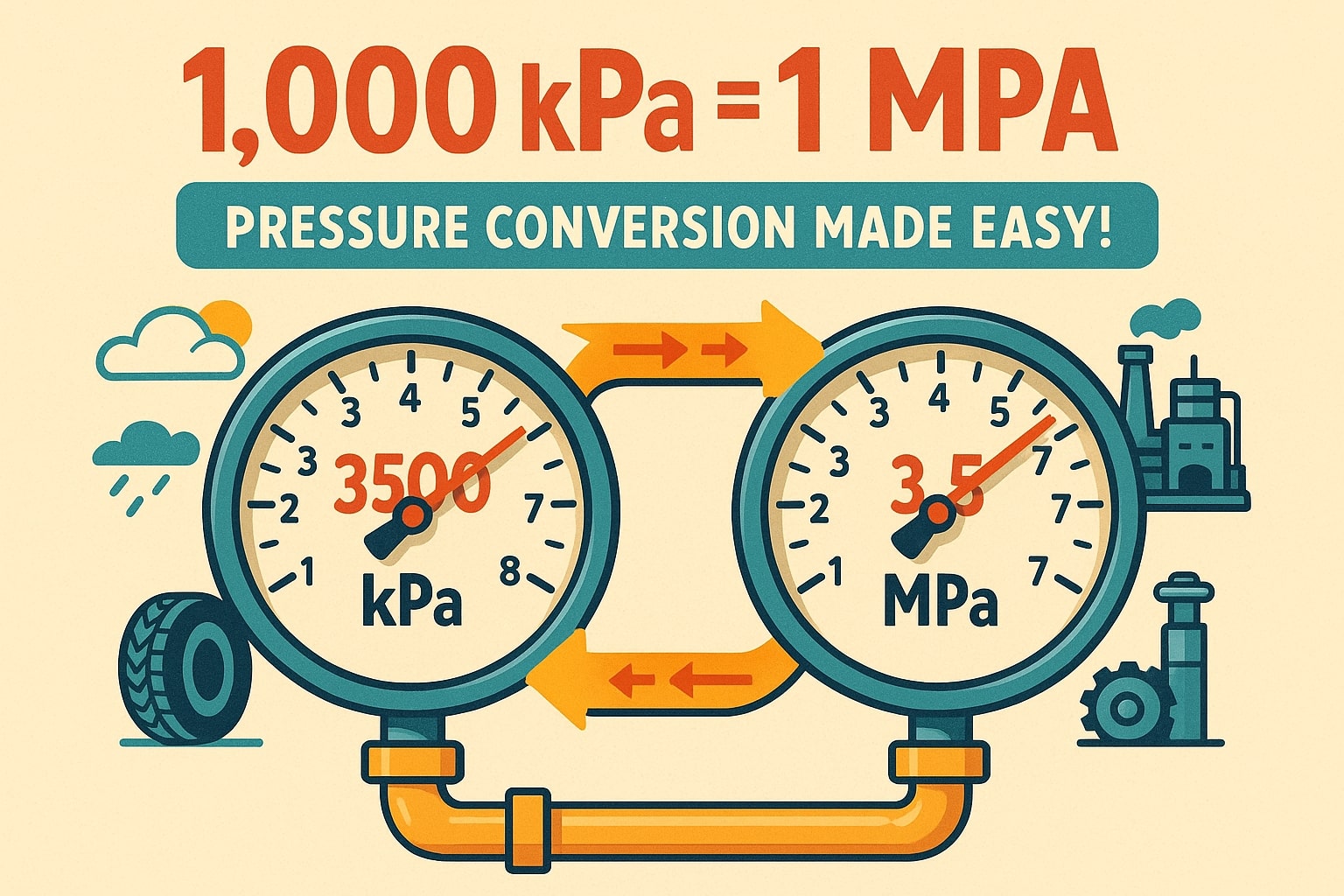

How to convert kilopascal to megapascal

The conversion is simple since both units scale directly from the pascal:

1 MPa = 1,000 kPa

To convert:

Megapascals (MPa) = Kilopascals (kPa) ÷ 1,000

Example: If a hydraulic press operates at 3,500 kPa:

3,500 ÷ 1,000 = 3.5 MPa

For quick, error-free conversions, use our Pressure Converter or check more Conversion tools to handle the math instantly.

Did you know?

-

Concrete strength standards: Many building codes specify concrete strength in MPa. Typical structural concrete ranges from 20 to 40 MPa, while specialized mixes can exceed 100 MPa.

-

High-pressure waterjets: Industrial waterjet cutters can reach pressures of up to 400 MPa — powerful enough to slice through steel, stone, and composites.

-

Pipeline safety: Long-distance gas pipelines often operate between 7 and 15 MPa, requiring strict testing to avoid catastrophic failures.

-

Automotive testing: Crash test facilities measure impact forces in MPa when analyzing material deformation in safety components.

When Megapascals Revolutionized Construction Standards

In the late 20th century, countries adopting the metric system began using megapascals to replace older, inconsistent pressure and strength units. According to reports from the International Standards Organization (ISO), building codes worldwide shifted to MPa for specifying concrete and steel strength, making it easier to compare materials across regions and suppliers.

This change allowed engineers to design safer, more standardized structures — from skyscrapers to bridges — while still being able to reference kilopascals for smaller systems like HVAC and hydraulics. The seamless scaling between kPa and MPa simplified engineering communication across all levels.

Converting with Confidence

Switching from kilopascal to megapascal is straightforward: divide by 1,000. While kPa is common for everyday systems and weather, MPa is essential for industries that deal with extreme pressures and material testing. Understanding both ensures accurate measurements across fields ranging from construction to advanced manufacturing.

For fast and reliable results, use our Pressure Converter or explore other Conversion tools to handle every pressure calculation effortlessly.