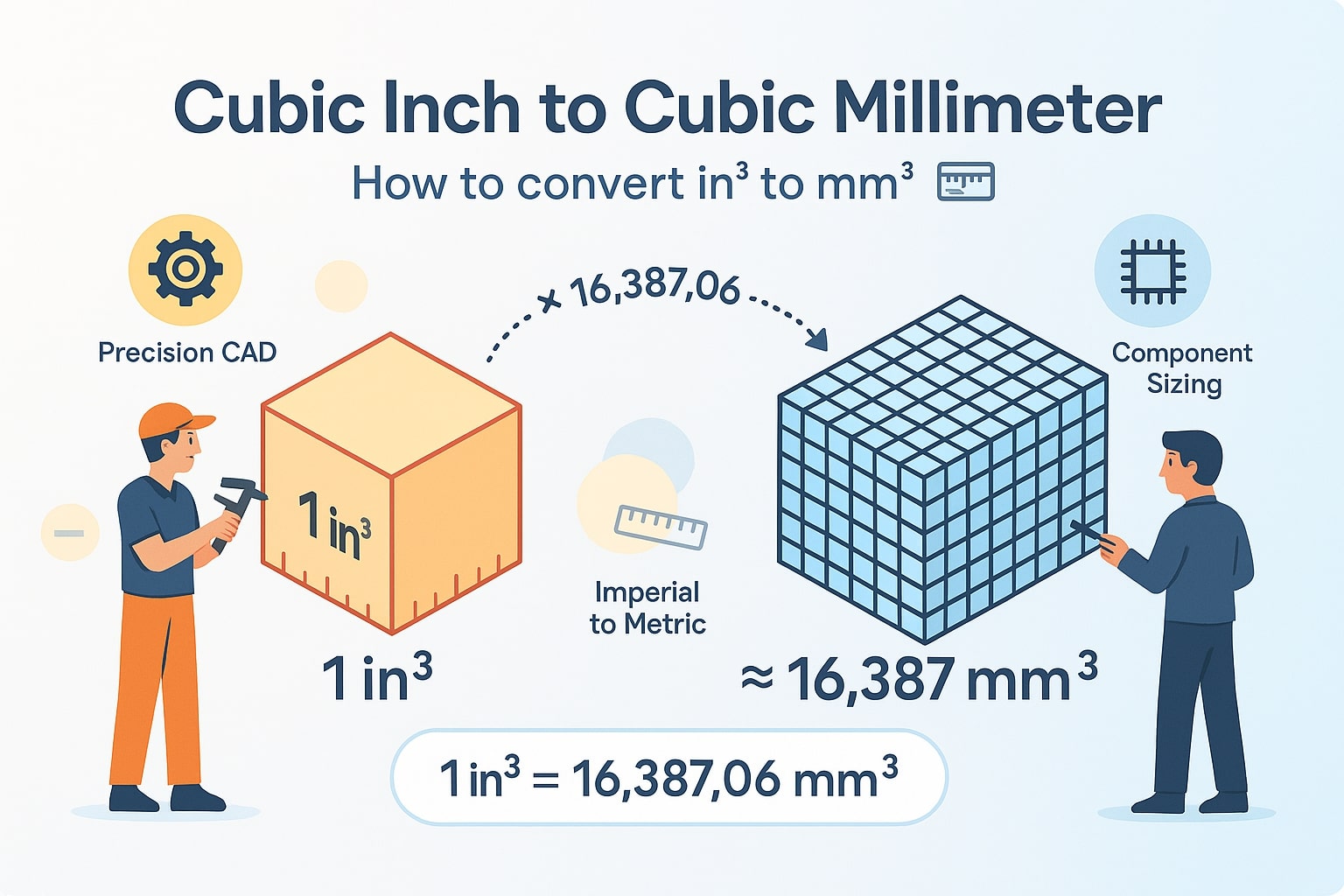

Cubic inch to cubic millimeter - How to convert in³ to mm³

If you’ve ever looked at a mechanical part blueprint or a product spec sheet, you’ve probably bumped into cubic inches (in³) and cubic millimeters (mm³). While they both describe volume, they sit on opposite ends of the measurement spectrum—imperial vs. metric, large scale vs. precision-level detail.

But don’t worry. Whether you're manufacturing tiny components or working with CAD designs, converting between them is actually quite simple—especially with Jetcalculator’s tools at your fingertips.

Small units, big difference

A cubic inch is the volume of a cube with each side measuring one inch. It’s a common unit in the U.S., particularly in automotive, manufacturing, and packaging industries.

A cubic millimeter, on the other hand, is extremely small. It's the volume of a cube with 1 mm sides—so small it’s used in medical syringes, microfluidics, and scientific lab measurements. If you're working in product design or medical device development, this is a unit you'll run into a lot.

The conversion formula

Here’s the quick math:

1 cubic inch = 16,387.064 cubic millimeters

So if you’ve got 3 in³, the conversion looks like:

3 × 16,387.064 = 49,161.192 mm³

No need to do this manually every time. Our Conversion tool handles this instantly. Or go straight to our Volume converter if you’re working with more than one volume unit.

Did you know?

-

In medical research, the average volume of a human tear is about 6.2 microliters—that’s just 0.0062 cubic centimeters, or 6.2 mm³. Measuring at this scale requires extreme precision.

-

The engine block of the 1970 Plymouth HEMI, famous in muscle car circles, had a volume of 426 cubic inches—that’s over 6.9 million cubic millimeters of raw V8 power.

-

Swiss watches, especially mechanical ones, operate within incredibly tiny clearances. Some components are just a few cubic millimeters in volume, showcasing the beauty of precision machining.

-

In 3D printing, especially in resin printing, model volume is often calculated in mm³ to optimize print cost, resin use, and curing time. That’s why slicing software almost always includes this unit.

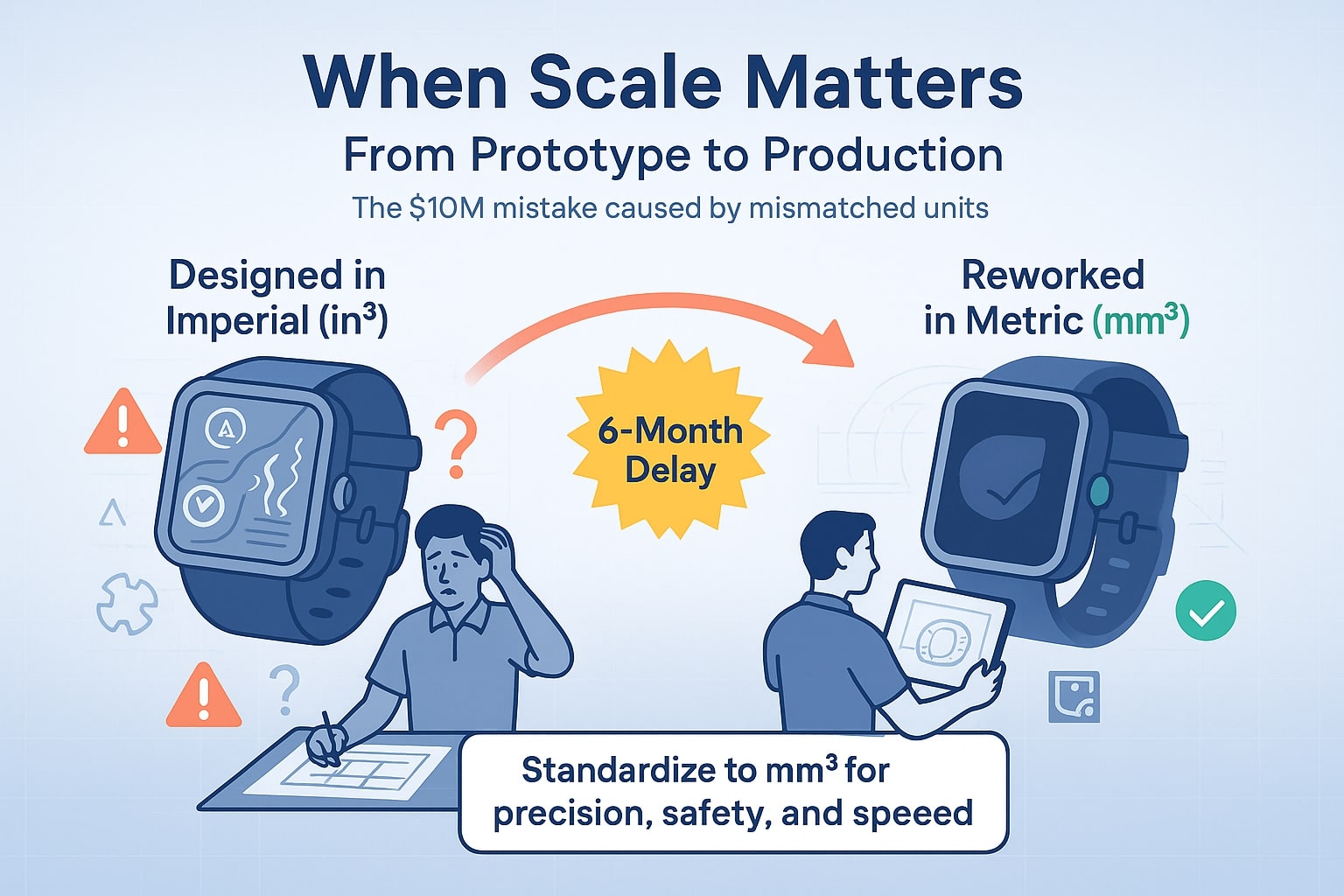

When scale matters: From prototype to production

In 2016, a well-known consumer electronics company had to delay production of a wearable device by nearly six months. The issue? The prototype was designed using imperial units, but the manufacturing plant overseas used metric. Tiny misalignments in cubic volume—just fractions of an inch—caused mismatched fittings, overheating, and failed drop tests.

The resolution? Standardizing all part specs to cubic millimeters, a unit far more precise and easier to use in automated CAD/CAM pipelines.

It’s a real-world example of how a simple unit conversion, if overlooked, can become a six-month, multi-million-dollar mistake.

Final thoughts

While cubic inches and cubic millimeters are separated by thousands of units, they often meet in engineering, design, and global manufacturing. Converting between them isn’t just helpful—it’s essential when you're working across systems or outsourcing internationally.

If you want precision, speed, and no headaches, let Jetcalculator do the math. Use our Volume converter for full flexibility, or the main Conversion tool when you need all units at your fingertips.